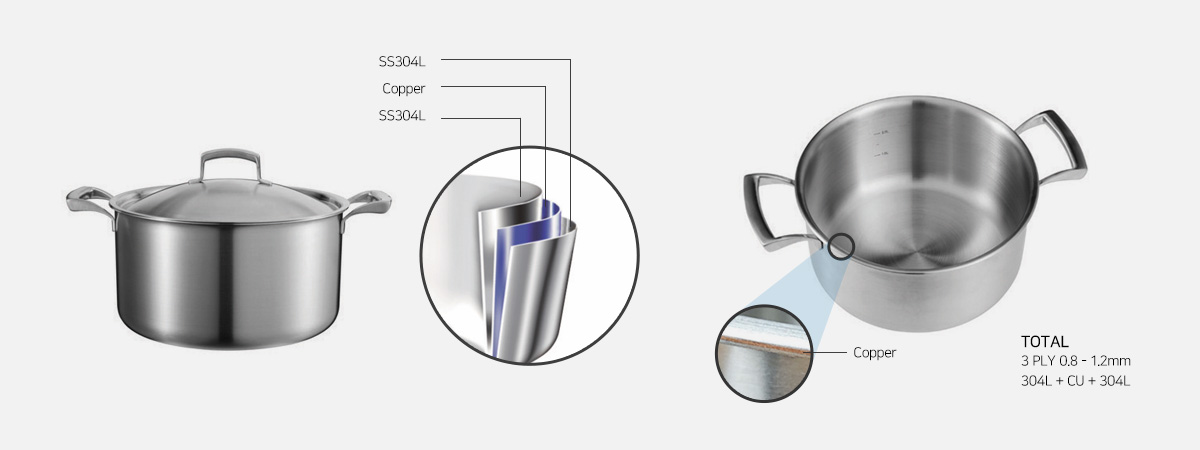

SCS 3 PLY + BOTTOM CAPSULE

For a typical stainless steel 3-ply clad, aluminium is inserted into the middle layer to increase thermal conductivity. SCS 3 PLY clad metal is a new version that maximizes thermal conductivity by inserting copper with higher thermal conductivity into the middle layer. SS304L is used on both sides to increase the corrosion resistance and to prevent discolorations on the surface. opper in the middle allows rapid transfer of heat throughout the product. Drawing performance is excellent with high elongation and 3 ply total thickness 0.8 to 1.2mm is available which can replace existing SS304 single product.

Comparison of Heat Conductivity of Each Material

Copper can increase thermal conductivity by 70% compared to gold or aluminum

| Material | Temperature(℃) | (㎏/㎡) | (㎉/㎏℃) | Heat Conductivity(㎉/℃) | (㎡/h) |

|---|---|---|---|---|---|

| Silver Gold Copper Aluminium Tungsten | 20 20 20 20 20 | 10530 19320 8300 2710 19300 | 0.056 0.031 0.10 0.214 0.032 | 360 254 320 196 170 | 0.613 0.425 0.370 0.340 0.275 |

SCS 3 PLY Structure

For Non-Induction : 304L + CU + 304L

For Induction : 304L + CU + 304L → Bottom capsule after processing

Copper which is high quality material and has high thermal conductivity is used in the middle to reduce the cooking time.

SCS 3 Ply targets high-end market with high quality and high-performance products.

It is getting attention as a unique product in the market where 3 ply aluminium-core products are popular.

Korea Clad Tech. Co., Ltd. 89, Dalseong2chadong 1-ro, Guji-myeon, Dalseong-gun, Daegu, Republic of Korea T.+82-53-670-1234 F.+82-53-617-1584

COPYRIGHT (C) 2019 KOREA CLAD TECH Co., Ltd. All rights Reserved